The sustainable alternative:

IMag S-ABSORB RAPID

Desulphurisation of biogas plants with iron hydroxide

The requirements for the desulphurisation of biogas processes are increasing. IMag S-Absorb RAPID, the sustainable iron hydroxide from IMagine, offers a solution. Our raw material is sustainable, made in Germany, REACH registered and undergoes continuous quality control. You are on the safe side with our iron hydroxide.

The sustainable solution for desulphurisation of biogas plants

Hydroxide IMag S-ABSORB RAPID is of natural origin

In Germany, streams, rivers and lakes are contaminated by iron-containing supply lines due to groundwater lowering as a result of mining. This has a massive negative effect on the ecology.

The polluted waters are extracted, cleaned and treated in a new process.

The aim is to clean the ecological systems with the downstream use of the active substances obtained in biological processes.

IMag S-ABSORB RAPIDcompared to previous processes

The iron products used in the European biogas industry are currently, as a rule, mined or produced in drinking water treatment through the use of iron chloride within the phosphate and heavy metal binding process.

IMag S-ABSORB RAPIDmakes the difference here:

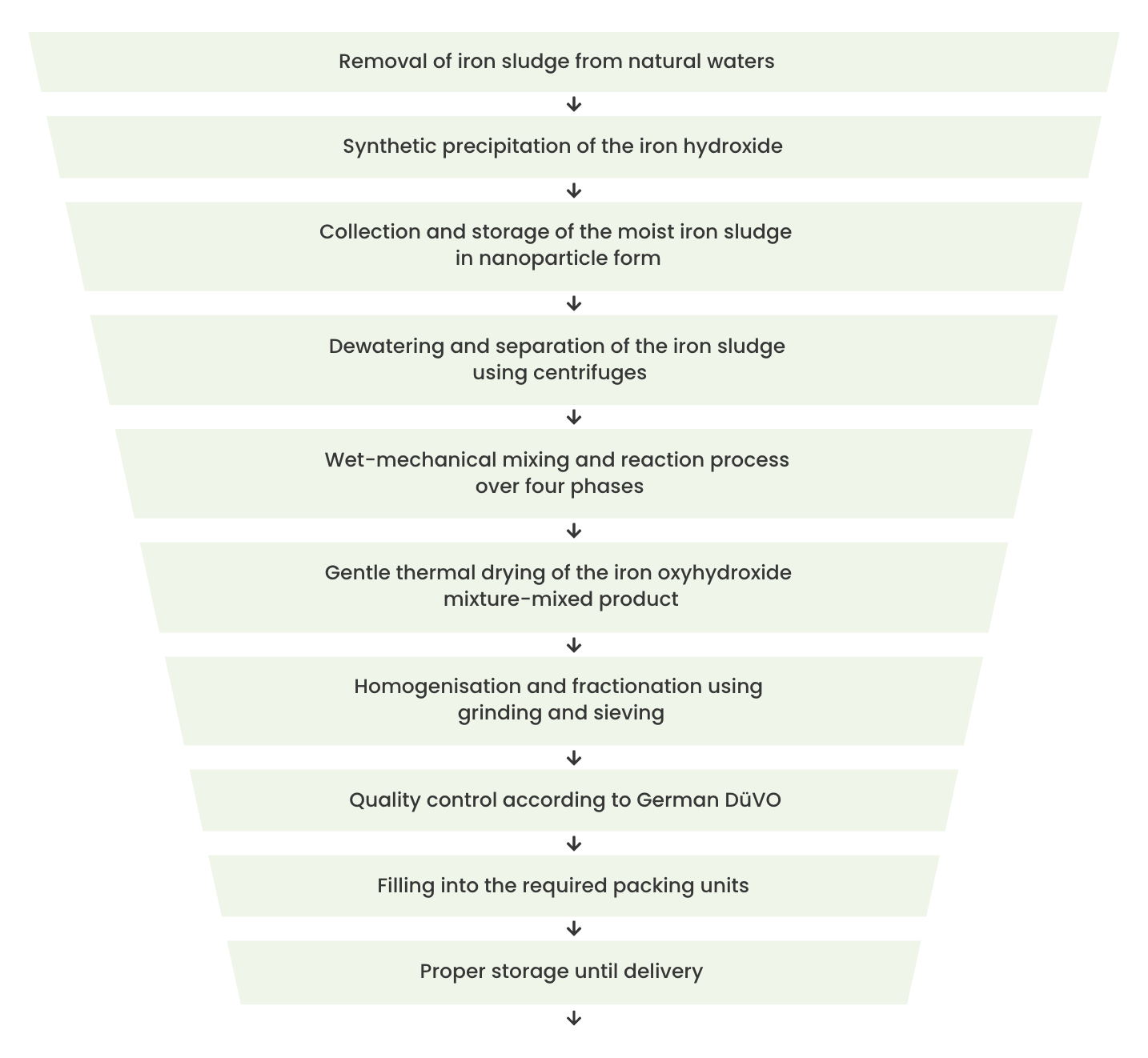

Production process of IMag S-ABSORB RAPID

Until now, the raw material could not be used to manufacture a high-quality product.

The technical problem was solved in a two-year process development programme.

IMag S-ABSORB RAPID

Iron hydroxide – from ecological problem to product

IMag S-ABSORB RAPID is effective and sustainable

It is obtained synthetically and prepared, ground and homogenised using a wet-mechanical process. Due to the large surface area of the individual particles, IMag S-ABSORB Rapid is very reactive and produces a rapid desulphurisation effect. Thanks to its high purity, IMag S-ABSORB Rapid can be applied with the substrate as a fertiliser after the desulphurisation process. The material is REACH registered.

Iron hydroxide is often used in biogas production as an H2S absorber to remove hydrogen sulphide (H2S) from biogas. This process helps to improve the quality of the biogas, as H2S is undesirable and has corrosive effects. Iron hydroxide reacts with H2S to form iron(II) sulphide (FeS), which removes H2S from the biogas. This is an important step in the upgrading of biogas before it is utilised as a renewable energy source.

Natural iron hydroxides

Mining

Different mineral phases

Energy-intensive preparation process

Partial binding of OH chains through geological processes

CO2 intensive transport chains

Mineralogy usually ferrihydrite (hydroxide mixed mineral)

Synthetic product Drinking water treatment

Ferric chloride application

Target: Phosphorus reduction

All base metals are bound

OH chains partially bound by P

High surface area due to < 1 micron, micron, high reactivity

IMag S-ABSORB RAPID

Sustainable raw material

Ecological approach

New, gentle production process

Free OH chains for sulphur binding

High chemical availability of the hydroxide component

Continuous quality control incl. batch-related certificates of analysis

IMag S-ABSORB RAPID – further advantages

- Fermentable sacks or big bags

- Customised labelling

- REACH Registered, DÜMV Table 8.1.4

- Hydroxide component chemically precipitated < 1 µm

- Raw material supply from sources in Germany

For further information, please do not hesitate to contact us.

If we have aroused your interest, please use our contact form and we will contact you immediately.

About IMagine and the Cofermin Group

The Cofermin Group, in Germany, is a successful, owner-managed and globally active company for raw materials and speciality chemicals with headquarters in Essen and representative offices worldwide. IMagine GmbH in Bad Oldesloe, as part of the Cofermin Group, distributes its products to a wide range of industries such as the foundry, steel, refractory, building materials, chemical, fertiliser and animal feed industries.